-

- New Energy Series

Photovoltaic DC isolating switch

Photovoltaic DC Molded Case Circuit Breaker

Photovoltaic DC miniature circuit breaker

- Power Distribution Series

- Terminal Series

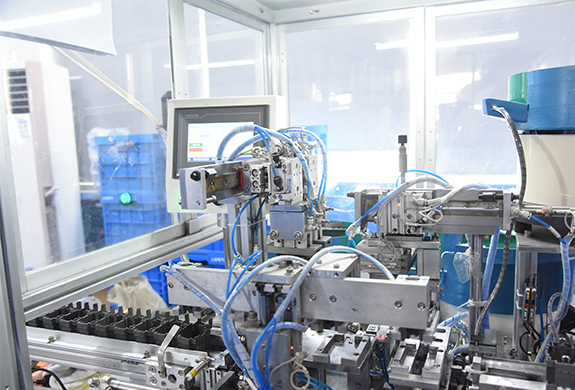

- Industrial Control Series

- Industrial Plug-in Device Series

Surface Mounted And Concealed Mounted Plugs And Sockets

Pc power supply maintenance box

- Isolating Switch Series

- Outdoor Waterproof Series

- New Energy Series